This post was initially written to provide background information for this article on the potential benefits of moving air conditioners to off peak power. (published by RenewEconomy on 21 Sept 2012) The article argues that that gradually moving air conditioners to off peak would allow most of the proposed power system upgrades to be deferred for a long time. The use of phase change materials (PCMs) to store cold or heat would allow this conversion to be done without reducing people's comfort levels.

PCMs are finding a markets as a compact way of storing heat or cold. This post provides background information

on the characteristics and uses of PCMs.

DEFINITIONS:

Phase:

Many materials can exist in more than one

phase. For example, water can exist in the solid, liquid or gas phase. Some materials can also exist as different

crystal phases.

Phase change: The change from one phase to another. For example, the melting of ice to

liquid water. Phase changes can be

driven by changes in temperature and/or pressure.

Phase change material (PCM): A mixture or pure substance that can change phase. The term is often restricted to materials

that change phase over a narrow temperature range.

Latent heat:

The heat that has to be added (or taken out) in order for the phase change to

take place. It is the high value of many latent heats that make PCMs so

useful for storing heat and cold. For

example, one kWh of heat will melt 10.8 kg of ice or raise the temperature of the same weight of liquid water

by about 80 deg C.

Heat flow: The

movement of heat from one place to another.

Thermal inertia: If something needs a lot of heat

(or cold) to change its temperature, it has high thermal inertia. For example, a 10,000 litre tank of water has more thermal inertia than a 100 litre tank. Traditional buildings

in hot dry areas are often built with thick, heavy walls to give high thermal

inertia so that the temperature inside the house doesn’t vary as much as it

does outside. Using PCMs to provide

thermal inertia reduces building weight as well as concentrating the thermal

inertia within the comfortable temperature range. (Note that, for keeping a building cool, the

PCM must get cold enough to freeze at some time during the day.)

Heat pump:

Heat pumps are used in most refrigerators, air conditioners and some hot water

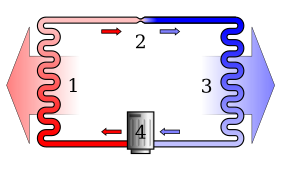

systems to “pump” heat from one place to another. This Wikipedia

diagram shows how a heat pump works:

Refrigerant gas is compressed in the

compressor (4). The hot compressed gas then flows to the condenser (1) where it

loses heat and condenses to liquid. The

liquid then flows through an expansion valve (2) to the evaporator (3) where it

absorbs heat and returns as cool, low-pressure gas

to the compressor. In effect, heat is

pumped from the evaporator to the condenser. The condenser can be used for

heating and the evaporator for cooling.

Reverse cycle air conditioners can be used for heating or cooling. The flow of refrigerant is reversed so that

the condenser becomes the evaporator.

Heat

pump COP (Coefficient of performance): The ratio

between the heat pumped and the energy consumed by the pump. COP drops as the difference between condenser

and evaporator temperature increases. Doubling the temperature difference will

approximately halve the COP. The “COP”

for a simple bar radiator is always 1.0 no matter what the temperatures are.

DESIRABLE PROPERTIES OF PCMS:

Desirable properties include:

1.

The phase change occurs

slightly below the desired temperature for cooling, above for heating.

2.

Phase change

occurs within a narrow temperature range.

3.

Low cost.

4.

Stability. Can be used indefinitely over a wide range of

temperatures without deteriorating.

5.

Tasteless and

odorless.

6.

Neither flammable

nor toxic.

7.

Can be safely

stored in a wide range of materials without causing corrosion problems.

WHAT PCMS ARE COMMERCIALLY AVAILABLE?

A wide range of PCMs are commercially

available. For example, UK

Development of commercial PCMs is

difficult. Most commercial PCMs don’t

have all the desirable properties listed above.

Choices may involve compromises.

The liquid/gas phase change is rarely used

to store energy because of the volumes required to store the gas. The exceptions are cases where it is

environmentally and economically acceptable to discharge the gas to

atmosphere. For example, liquid

nitrogen is commonly used to store cold when temperatures as low as -196 deg C

are required.

Dry ice (solid CO2) uses a

solid/gas phase change to store cold at -78.5 deg C.

HOW MUCH DO PCMS COST?

The cost of PCMs varies considerably

because of the different raw materials used in their manufacture. Indicative data supplied by Australian

manufacturer PCP

Australia (Jan 2012) suggests it

would cost $70 to buy enough of their PC25 product to

store one kWh of heat. By contrast, the

equivalent cost for their PC17 product

would be about $150. PC17 costs more

because the mix contains bromides instead of chlorides. (PC25 melts at 25 deg C. About 15 litres of either product is required to store one kWh of heat or cold.)

APPLICATIONS:

Both the PCM Products and

PCP Australia websites provide

information on ways in which PCMs are used and how PCMs can be incorporated

into various materials. Smart

Planet provides a wider view of the possibilities.

Example: Using PCMs to allow air

conditioning to move to off peak power:

In countries such as Australia

Switching air conditioners to controlled

power would only be acceptable to the community if people’s comfort is not

affected. Using PCMs to store heat or

cold while the heat pump is running would be one logical approach to protecting

comfort. PCM storage is attractive

because relatively little space is required.

Approaches that might be considered include:

1.

Leaving existing

air conditioners unchanged and installing PCM based products within the building

rooms. Products such Dupont

Energain Thermal Mass Panels might be used to do this. One disadvantage of this approach is that the

panels will continue to heat/cool the building when this is not needed. (Think of a house that is empty while the

occupants are at work.) Another

disadvantage is that the building may need to be kept hotter or colder than desirable

while heat/cold is being stored. OR

2.

Locating the heat/cold

storage outside of the in an insulated storage tank. The air conditioner system would be modified

so that the heat pump pumps heat/cold to the storage tank. Cold (or hot) water from the tank is then

pumped to the rooms for temperature control.

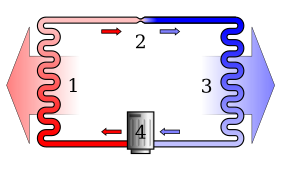

This PCB Australia

circuit shows one way that this could be done. The tank contains water and

the PCM. The water in the tank would be physically separated from the PCM to

avoid contamination.

Apart from solving the peak power problem,

the use of PCM storage in air conditioning systems saves money for the consumer

by allowing:

1.

Low-cost off-peak

power to be used to run the heat pump.

2.

Average power

consumption to be reduced. (The

compressor would be scheduled to run at times of the day when outside

temperatures are closer to the storage temperature. (See “Heat pump COP” above re the benefits of

doing this.) This link gives average monthly

maximum and minimum temperatures for various Australian locations and times of

the year. The differences between maximum and minimum temperatures are

sufficient to make the power savings significant.

Solar hot water heating may provide a

better source of heat than heat pumps in some locations.

DISCLAIMER:

John Davidson is not associated with any

organization that profits from sale PCMs.

John,

ReplyDeleteMoving air-conditioning and cold-store demand to off-peak periods can save a tremendous part of the cost of the electricity grid.

This message just isn't getting through. The Productivity Commission, Ausgrid and the Government are all push for smart meters and Dynamic Peak Pricing.

1 The capital cost of the smart meter rollout is enormous.

2. Dynamic Peak Pricing belatedly creates the demand for air conditioners that use Phase Change Materials to shift load to off-peak periods. People will notice this when they are charge 70 cents per kWh to use their existing air-conditioner during heat waves.

3. A smart meter rollout is a very expensive and long-winded "interim step" to introduce grid-friendly air-conditioners that spread demand uniformly by using electricity during off-peak periods.